Hardanger Bridge

N: 60°28'45.0" E:6°49'46.0"

Dehumidification

Belvent A/S was responsible for establishing the dehumidification system for the main cables in connection with the construction of the bridge.

With a main span of 1,310 meters—30 meters longer than the Golden Gate Bridge—the Hardanger Bridge is Norway’s longest suspension bridge. The pylons rise more than 200 meters, and the bridge opened to traffic in 2013.

The bridge is one of the key landmarks in Norwegian infrastructure, making correct and optimal maintenance essential to ensure that the bridge in the scenic Vestland region remains in service for many years to come.

Dehumidification and airtight sealing of the main cables are the primary measures used to protect the cables against the effects of corrosion and rust—an alternative to paint, which had previously been used on similar structures.

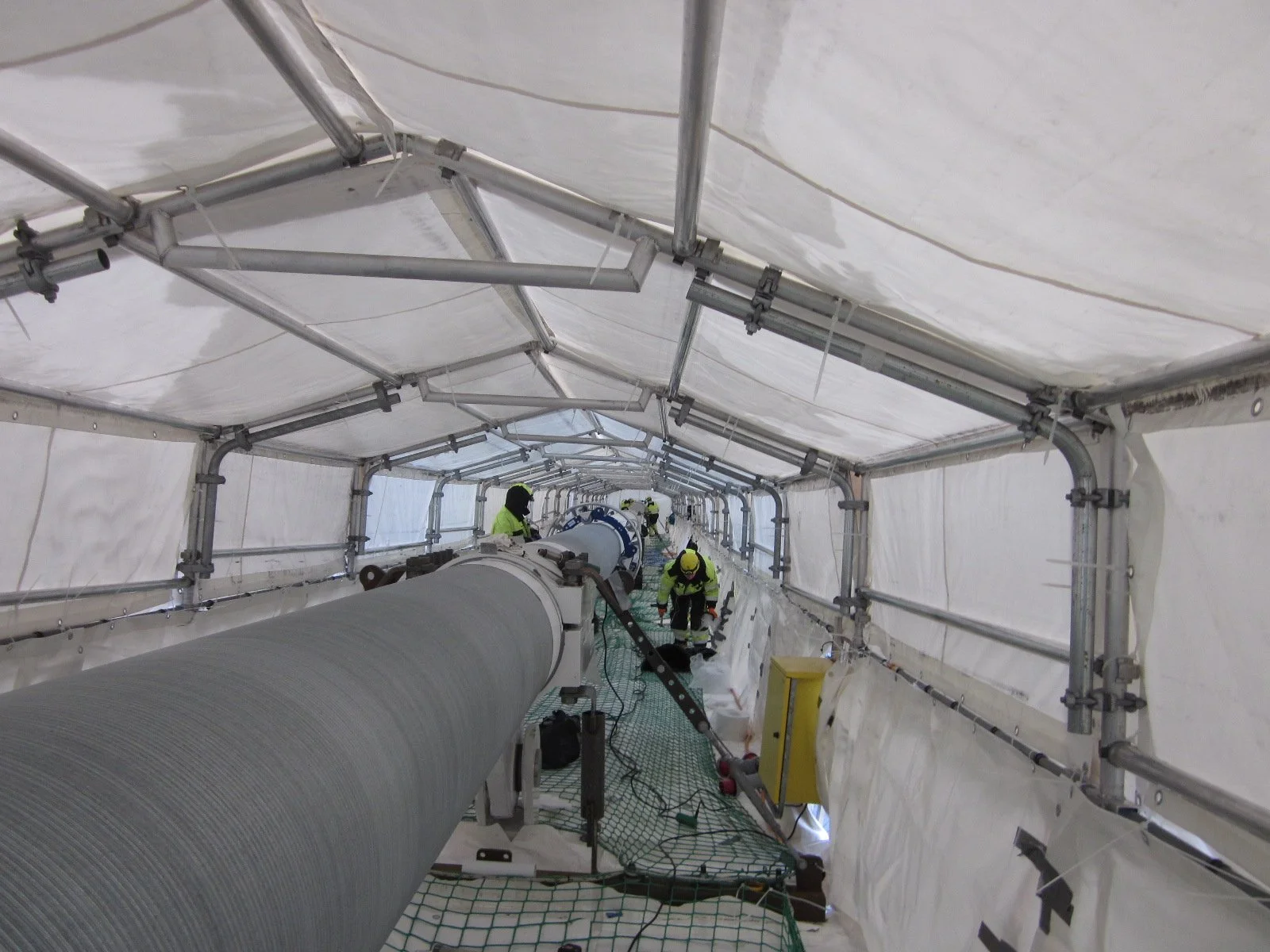

Wrapping

The project, including the dehumidification of the main cables, was carried out in close collaboration with Ommen A/S (formerly Ommen & Møller) and Davai, who were responsible for the successful wrapping and airtight sealing of the main cables.

Service

Following handover of the project to the client, Belvent has performed ongoing service during the warranty period.

This included, among other tasks, the replacement of all filters and inspection of instruments in 2016.

Additional Works

In addition to dehumidifying the bridge itself and its main cables, Belvent also handled the dehumidification of the individual wires that make up the main cables, prior to their installation.

This involved dehumidifying more than 200 twenty‑foot containers, which had to be kept dry (below 45% RH) until the wires were installed on the bridge.

Project Partners:

MT Højgaard (Main Contractor, Steel & Installation Works)

Ommen A/S (Ommen og Møller)

Davai A/S

Fyns Energiteknik A/S

COWI A/S

Statens Vegvesen